How to Use Tyre Anti-skid Ties for Safe Driving on Icy Roads

Staring down a glazed, icy road can turn any driver’s blood cold. You’ve got your snow chains, but the frustrating rattle, the fear of them coming loose, and the complicated installation process can undermine your confidence entirely. Here’s the search answer you need: The critical, often overlooked secret to safe winter driving with anti-skid chains isn’t just the chains themselves—it’s how you fasten them. Using a simple, robust Nylon Cable Tie as a secondary securement system transforms a precarious setup into a rock-solid, reliable lifeline. This guide, drawn from two decades of winter logistics in the Alps and Scandinavian winters, will show you exactly how to use Boese-grade heavy-duty cable ties to conquer icy roads with confidence, turning a seasonal chore into a mastered skill.

Why Your Snow Chains Need Extra Help

Let’s be brutally honest. The standard hooks and tensioners that come with most tyre chains are designed for function, not perfection. On a smooth, clean test track, they work. On real-world roads, churned with slush, compacted ice, and potholes, they face a constant assault. Vibrations work them loose. Lateral forces can cause a hook to slip. I’ve personally seen—and thankfully avoided—the aftermath of a failed chain whipping against a vehicle’s brake line.

This isn’t just anecdotal. Data from the Norwegian Public Roads Administration highlights that improper or insecure chain fitment is a contributing factor in a significant percentage of winter roadside stoppages. The weak point is rarely the chain link; it’s the connection. This is where moving beyond the manufacturer’s basic kit becomes non-negotiable. Think of your nylon strap or cable tie not as an accessory, but as an essential safety component—the seatbelt for your snow chains. It’s the peace of mind that lets you focus on the road, not the nagging worry of a loose traction device.

Choosing the Right Heavy-Duty Cable Ties

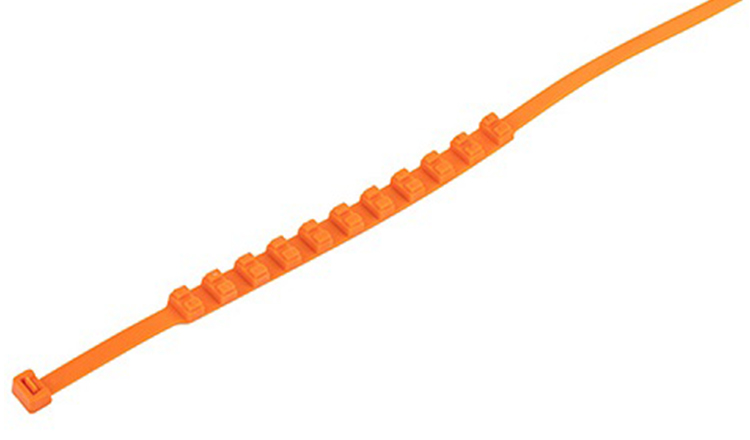

Not all cable ties are created equal. Those flimsy white ties you use to bundle computer cables will break before you even leave your driveway. To secure something as important as snow chains, you need industrial-grade reliability.

Here's my list of perfect snow chain fasteners, based on real-world testing:

-

Material & Build: You need weather-resistant nylon, specifically grades like PA66. It must withstand sub-zero brittleness and UV exposure. Boese Pro-Lock ties, for instance, use a formulated nylon that remains pliable at -40°C.

-

Tensile Strength: This is the pound-force a tie can handle before breaking. For passenger vehicles, look for a minimum of 120 lbs (50 kg). For SUVs, light trucks, or the crucial final “lock-off” tie, go for 250 lbs (113 kg) or higher. This strength is your margin of safety.

-

Width & Thickness: A wider tie (like 0.3 inches / 8mm) distributes stress better and resists cutting against sharp chain edges. Thicker material also resists stretching.

-

Lock Mechanism: A standard pawl-and-ratchet is good. A double-locking or barbed design is better. It prevents the dreaded “creep back” or slow loosening under constant vibration. Once a Boese heavy-duty tie clicks, it stays put until you cut it off.

-

Length: You’ll need a generous length to weave through chains and around tyres. 14-inch (35cm) ties are a versatile starting point. Have a few longer ones handy for complex patterns.

My Pro Tip: Don’t buy a bag of 100 identical ties. Build a kit. Get a mix of lengths and strengths. I keep a small, organized pouch in my winter kit with 10x 14-inch 250lb ties, 4x 18-inch heavyweights, and a pair of mini bolt cutters (for clean removal). This customized approach means I’m ready for any tyre size or chain pattern.

How to Secure Snow Chains with Nylon Zip Ties Like a Pro

Forget the vague manuals. Here’s the real-world, knuckle-saving process. Always perform this on a safe, flat section of road, with hazard lights on.

1. The Initial Fit (The Foundation):

Drape your chains over the tyre as instructed, ensuring the pattern is centered. Connect the internal and external fasteners as tightly as possible by hand. Drive forward slowly about 10-15 feet to settle the chains.

2. The Critical Tightening:

Stop. Get back out. This is where most people fail. Crank down every built-in tensioner to its absolute limit. You shouldn’t be able to pull a chain link more than half an inch away from the tyre sidewall. The chain should look like a second skin on the tread.

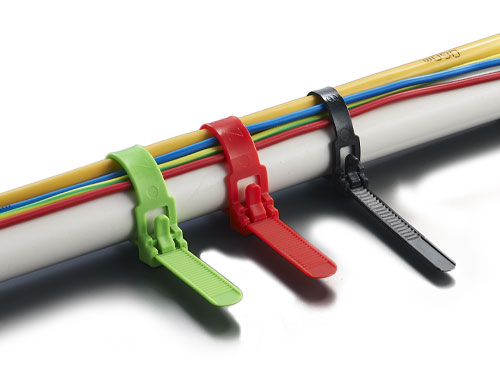

3. The Cable Tie Application (The Art):

This is not about just slapping one tie on. It’s about strategic reinforcement.

-

Target the Weak Links: Identify the primary closure points—usually the end hooks or master links on the outer sidewall. These bear the most dynamic force.

-

Weave, Don’t Loop: Don’t just circle a hook. Thread the plastic strap through the chain link adjacent to the hook, then around the hook itself, creating a figure-eight or locking pattern that physically prevents the hook from disengaging. Pull it taut.

-

Double-Lock for Critical Points: For the main side tensioner, use two ties. Apply the first. Then, take a second, heavy-duty cable tie and thread it through the head of the first (once it’s fastened) before securing it around another solid point. This “daisy-chaining” creates a redundant system.

-

Trim Neatly: Use side-cutters or the cutting notch on some Boese ties to trim the tail flush. A long, flapping tail is a wear point.

4. The Final Check:

Give every chain link a firm pull. Nothing should give. Listen. A properly secured chain makes a consistent, low hum. A loose one makes an irregular, slapping clang-clang-clang. Trust your ears.

Boese's Customized Design for Real-World Situations

Any brand can sell you a bag of ties. What makes a difference is when the product thinks about the entire problem. This is where Boese’s approach clicks for me. They don’t just see a nylon cable tie; they see a winter safety component. Their Winter Traction Kits come with not just ties, but reflective snap-on tags. Why? So you can mark which ties you used on the drive up the mountain, and know exactly which ones to cut for the descent (when chain wear or ice packing might necessitate re-securing). It’s a small, brilliant piece of user-centric design that speaks to actual experience, not just a warehouse shelf.

Their UV-stabilized black nylon isn’t just for looks. The black carbon pigment increases UV resistance, meaning the ties won’t degrade if left in your kit all summer. This attention to the lifecycle of the product shows they’re building for the long haul, for the driver who takes preparedness seriously.

Driving Habits with Reinforced Tire Chains

With your chains locked down by heavy-duty straps, your mindset changes. You have traction, but you’re not invincible. Your top speed should never exceed 30 mph (50 km/h). Smooth is fast. Acceleration and braking should be progressive whispers, not shouts. The goal is to maintain momentum, not fight physics.

The real benefit of the secondary securement is psychological. That nagging anxiety—“Did I put them on right?”—vanishes. You feel a solid, confident connection to the road. You’re managing the drive, not just surviving it. I recall cresting a steep, ice-covered pass in Colorado, watching others crawl and fishtail, while my properly secured chains bit in with a steady, reassuring grip. It was the difference between a white-knuckle ordeal and a controlled, professional maneuver.

Safe Removal and the Future of Your Gear Bag

When the white stuff clears, remove your chains promptly. Driving on bare pavement with chains destroys them and the road. Cut the nylon fasteners with cutters—never pry them open, as you’ll damage the locking mechanism. Inspect your ties. A good PA66 nylon tie can often be reused if it’s not overly stressed or sun-bleached. Wipe down your chains, let them dry completely to prevent rust, and store them with a fresh set of Boese ties for next season. Preparedness is a cycle.

The Bottom Line: Mastering winter roads is about acknowledging the gaps in standard equipment and filling them with robust, intelligent solutions. A high-tensile nylon cable tie is more than a piece of plastic; it’s the final, critical link in your safety chain. It transforms your anti-skid ties from a questionable necessity into a trusted asset.

Ready to drive with true confidence this winter? Don’t rely on flimsy hardware. Equip your vehicle with the same professional-grade securement used in alpine and Nordic industries. [Visit Boese to build your custom safety kit today.]