A Complete Guide to Nylon Cable Ties

Nylon cable ties, also known as zip ties, are indispensable fasteners widely used across industries and daily life for organizing, bundling, and securing cables, wires, and various objects. Renowned for their durability, flexibility, and cost-effectiveness, nylon cable ties have become a staple in electrical work, automotive manufacturing, construction, and even household organization. This comprehensive guide will unpack everything you need to know about nylon cable ties, from their definition and origin to their types and applications.

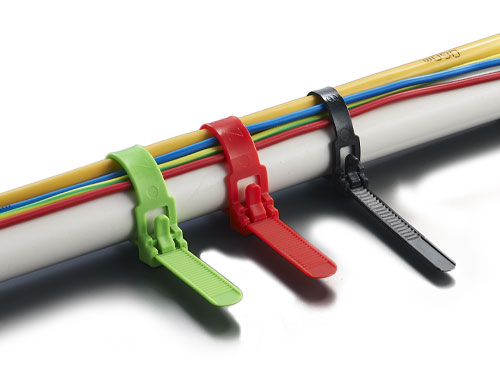

What is a nylon cable tie?

A nylon cable tie is a one-piece fastening device made primarily from high-grade nylon, most commonly nylon 66 (PA 66), which offers excellent tensile strength, chemical resistance, and temperature adaptability. The classic design features a flexible strip with evenly spaced teeth along one side and a self-locking head at one end. When the strip is inserted into the head, the teeth engage with a pawl inside, creating a secure, non-releasable bond (unless designed as reusable) that tightens as tension is applied.

Standard nylon cable ties boast a fire rating of UL 94 V-2 and operate within a temperature range of -40°C to 85°C (-40°F to 185°F), making them suitable for most indoor and general outdoor applications. Their key advantages include quick installation, insulation properties, resistance to acids, greases, and moisture, as well as affordability for bulk use—factors that have solidified their position as the dominant cable tie type, accounting for over 78% of global consumption.

Who invented nylon cable ties?

The nylon cable tie traces its origins to 1958, when Maurus C. Logan, a research and development executive at Thomas & Betts (an American electrical components company), invented and patented the device under the brand name “Ty-Rap”. Logan’s inspiration struck two years earlier, in 1956, during a visit to a Boeing aircraft factory. He observed workers struggling to bundle thousands of feet of aircraft cables using waxed nylon cord, a labor-intensive process that often resulted in cut fingers and inefficiency.

Determined to create a better solution, Logan developed a two-part design with a plastic strip and a metal pawl for locking. However, the design was soon refined to a fully nylon construction—eliminating the metal component to reduce cost and improve manufacturability. Initially intended for use in aerospace wiring, the nylon cable tie quickly gained traction across various industries due to its simplicity and reliability. Logan’s invention remains one of the most enduring fastening solutions, with Thomas & Betts later acquired by ABB in 2012, continuing to produce the iconic Ty-Rap ties.

What are the different types of nylon cable ties?

Nylon cable ties have evolved into a diverse range of types, each engineered for specific environments, loads, and applications. Below are the most common variants:

1. General-Purpose Nylon Cable Ties

Made from standard nylon 66, these are the most widely used ties for indoor and mild outdoor tasks. They offer tensile strength ranging from 18 lbs to 120 lbs, making them ideal for organizing electrical cables, home appliances, and office wiring. Operating at -40°C to 85°C, they meet UL 94 V-2 fire standards and are cost-effective for bulk purchases.

2. UV-Stabilized Nylon Cable Ties

Formulated with carbon black additives to resist ultraviolet radiation, these ties are designed for long-term outdoor use. Natural nylon ties degrade quickly under direct sunlight, but UV-stabilized black variants maintain durability in rooftop telecom equipment, solar panel wiring, and construction sites. In 2024, over 31 billion UV-stabilized nylon ties were used globally, a 17% increase from 2023.

3. Heat-Stabilized Nylon Cable Ties

Engineered to withstand higher temperatures, these ties operate from -40°C to 120°C (with short-term peaks up to 150°C). They are critical for under-hood automotive applications, HVAC units, industrial machinery, and power inverters—environments where standard nylon would melt or become brittle.

4. Releasable (Reusable) Nylon Cable Ties

Featuring a modified locking mechanism that allows for easy release and reusability, these ties reduce waste in temporary setups. Popular in warehouse logistics, retail signage, and prototyping, they sold over 36 billion units in 2024, with 58% used in commercial and industrial facilities.

5. Flame-Retardant Nylon Cable Ties

Meeting UL 94 V-0 fire standards, these ties are essential for high-safety environments like data centers, electrical cabinets, and transport tunnels. Globally, over 22 billion flame-retardant nylon cable ties are used annually, primarily in automotive wiring harnesses and aerospace components.

6. Heavy-Duty Nylon Cable Ties

Thicker and wider than standard ties, heavy-duty variants offer tensile strength up to 300 lbs. They secure large cable bundles, industrial machinery, and outdoor conduits, making them indispensable in data centers and power distribution systems.

7. Biodegradable Nylon Cable Ties

Driven by environmental regulations, these ties are made from PLA or compostable polymers. Expected to represent 5% of total production by 2025, they are popular in Europe and North America for sustainable projects.

Conclusion

Nylon cable ties have evolved significantly since their origins in aerospace, becoming a versatile fastening solution that powers industries worldwide. From general-purpose indoor organization to extreme outdoor and high-temperature environments, there is a nylon cable tie tailored to every need. Their low cost, durability, and adaptability have made them a cornerstone of electrical, automotive, and construction workflows—with market demand continuing to grow alongside industrial automation and renewable energy expansion.

When selecting a nylon cable tie, consider factors like temperature range, UV exposure, tensile strength, and compliance with safety standards to ensure optimal performance. Whether for household use or large-scale industrial projects, the right nylon cable tie simplifies organization, enhances safety, and delivers long-lasting reliability.