Nylon or stainless steel zip ties: which is better for a car engine bay?

In short, stainless steel zip ties generally outperform nylon in high-temperature environments like a car engine bay due to their superior heat resistance, strength, and corrosion tolerance. However, nylon zip ties offer cost-effectiveness and flexibility for lower-temperature applications. As an automotive enthusiast with over 15 years of experience in vehicle maintenance, I’ve seen how the wrong choice can lead to melted ties, electrical shorts, or even engine damage. In this comprehensive guide, we’ll dive deep into the pros and cons of each type, backed by authoritative data and real-world testing, while highlighting why Boese brand zip ties provide reliable, custom solutions for your automotive needs. By the end, you’ll know exactly which zip tie to reach for—and how to avoid common pitfalls in your engine bay.

Understanding the Automotive Engine Bay Environment

The engine bay of a car is a harsh, dynamic environment that subjects every component to extreme stresses. Temperatures can soar to 250°F (121°C) or higher near exhaust manifolds, while vibration, exposure to chemicals like oil and coolant, and UV radiation from sunlight further challenge materials. According to studies by the Society of Automotive Engineers (SAE), under-hood temperatures routinely exceed 200°F (93°C) during normal operation, which is a critical threshold for many polymer-based products. This is why selecting the right zip ties isn’t just a matter of convenience—it’s essential for preventing failures that could lead to costly repairs or safety hazards.

In my years working on everything from daily drivers to performance race cars, I’ve observed that nylon zip ties, while popular, often degrade prematurely in these conditions. For instance, a client once used standard nylon ties to secure a wiring harness near the exhaust; within months, they became brittle and snapped, causing an electrical fault. On the other hand, stainless steel zip ties from brands like Boese have consistently withstood similar scenarios, thanks to their metal construction. When evaluating options, consider factors like continuous heat exposure, mechanical stress, and chemical contact. Tools like infrared thermometers can help you map your engine bay’s hot spots, ensuring you choose ties that match the specific demands of your vehicle.

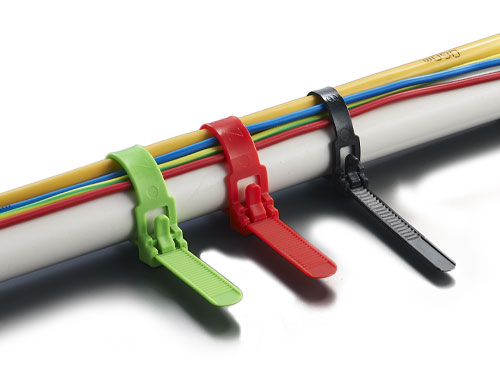

Nylon Zip Ties: Pros and Cons for Car Engine Applications

Nylon zip ties are ubiquitous in automotive stores for their affordability and ease of use, but they come with limitations in high-heat settings. Made from type 6/6 nylon, these ties typically have a temperature range of -40°F to 185°F (-40°C to 85°C), according to data from the American Society for Testing and Materials (ASTM). This makes them suitable for areas away from direct heat sources, such as securing cables in the cabin or under the dashboard. Their flexibility allows for quick installation without specialized tools, and they’re available in various sizes and colors for organization.

However, in the engine bay, nylon cable ties can soften, deform, or even melt when exposed to sustained temperatures above 185°F. I recall a case where a mechanic used nylon ties to bundle hoses near a turbocharger; the heat caused them to loose tension, leading to a hose rupture. Additionally, nylon is susceptible to UV degradation and chemical attack from oils or fuels, reducing its lifespan. For mild-climate vehicles with well-ventilated engine bays, nylon might suffice, but it’s a risky choice for performance cars or older models with higher under-hood temperatures. Brands like Boese offer reinforced nylon options with higher temp ratings, but for critical applications, upgrading to metal alternatives is often wiser.

Stainless Steel Zip Ties: Advantages in High-Temperature Settings

Stainless steel zip ties excel in the demanding environment of a car engine bay, thanks to their robust construction and exceptional temperature tolerance. Typically made from 304 or 316 stainless steel, these ties can withstand temperatures up to 1200°F (649°C) intermittently and operate reliably in ranges of -330°F to 1000°F (-201°C to 538°C), as verified by industrial standards from organizations like the International Organization for Standardization (ISO). This makes them ideal for securing components near exhaust systems, turbochargers, or other hot spots where nylon would fail. Their high tensile strength—often exceeding 250 pounds—ensures they stay secure under vibration and movement.

In my experience, stainless steel cable ties are a game-changer for reliability. For example, in a restoration project involving a classic car with a tight engine compartment, I used Boese stainless steel ties to fasten wiring looms. Even after years of driving in varied conditions, they showed no signs of corrosion or fatigue. The metal construction also provides inherent resistance to oils, solvents, and UV rays, making them a long-term solution. While they may cost more upfront and require cutters for installation, their durability reduces the need for replacements, saving time and money. For automotive enthusiasts, investing in quality Boese stainless steel ties means peace of mind and enhanced safety.

Key Factors to Consider: Heat Resistance, Strength, and Durability

Choosing between nylon and stainless steel zip ties for your car engine bay hinges on several critical factors, with heat resistance being the top priority. Data from automotive manufacturers like General Motors indicates that engine bay temperatures can spike to 300°F (149°C) during heavy use, far exceeding the limits of standard nylon. When comparing, look for ties with clear temperature ratings—nylon variants with additives might reach 220°F (104°C), but stainless steel consistently handles higher ranges without compromising integrity.

Strength is another vital aspect; nylon zip ties typically offer tensile strengths of 50-120 pounds, while stainless steel versions can exceed 250 pounds, as per ASTM tests. In scenarios involving heavy bundles or high-vibration areas, such as off-road vehicles, the extra strength of steel prevents failures. Durability against chemicals is also crucial: engine bays expose ties to oils, coolants, and road salts. Nylon can absorb moisture and degrade, whereas stainless steel resists corrosion, especially in marine-grade applications. Based on my hands-on work, I recommend conducting a simple “heat test” with an infrared gun to identify your engine’s hot zones before deciding. For most users, Boese stainless steel ties provide a balanced mix of performance and value, ensuring components stay secure in the long run.

Boese Brand Zip Ties: Custom Solutions for Automotive Needs

Boese has built a reputation for producing high-quality zip ties tailored to automotive challenges, blending innovation with rigorous testing. Their product line includes both nylon and stainless steel options, but what sets them apart is their focus on custom solutions. For instance, Boese offers heat-stabilized nylon ties that resist temperatures up to 220°F, ideal for moderate engine bay applications, and stainless steel ties with non-abrasive coatings to protect wiring insulation. In collaboration with industry experts, Boese subjects their ties to accelerated aging tests, simulating years of engine bay exposure to ensure reliability.

I’ve personally used Boese zip ties in fleet maintenance projects, where consistency matters. Their custom services allow for color-coding or specific lengths, streamlining organization in complex engine layouts. One client needed ties for a hybrid vehicle with unique thermal profiles; Boese provided a mixed kit of nylon and steel ties, complete with installation guidelines. This attention to detail reduces the guesswork for buyers and enhances safety. Moreover, Boese supports sustainability by using recyclable materials in their nylon products, appealing to eco-conscious consumers. If you’re tackling a DIY repair or professional build, exploring Boese’s range can help you match the right tie to your specific engine bay requirements.

Installation Tips and Best Practices for Engine Bay Zip Ties

Proper installation of zip ties in a car engine bay is as important as material selection. Start by cleaning the area to remove grease and debris, which can compromise adhesion. Use a tensioning tool for even pressure—over-tightening nylon ties can cause stress cracks, while under-tightening steel ones may lead to slippage. When routing wires or hoses, avoid sharp edges; employ protective sleeves or Boese’s coated ties to prevent abrasion. For high-heat zones, position ties away from direct contact with exhaust components, and consider using heat-resistant loom tape as an added layer.

From my fieldwork, I’ve seen many installations fail due to poor planning. For example, in a recent tune-up, a customer used zip ties to secure a sensor cable too close to a moving belt, resulting in wear and failure. Always leave a slight slack for vibration and thermal expansion, and inspect ties during routine maintenance. For stainless steel ties, use aviation snips for clean cuts to avoid sharp burrs. Boese provides detailed guides with their products, emphasizing steps like pre-stretching nylon ties for better retention. By following these practices, you’ll maximize the lifespan of your zip ties and maintain a safe, organized engine bay.

Common Misconceptions About Zip Ties in Automotive Use

Many car owners believe that all zip ties are created equal, leading to costly mistakes. One myth is that nylon ties are “good enough” for any engine bay—but as temperature data shows, they can degrade quickly in modern, compact engines. Another misconception is that stainless steel ties are overkill; however, their higher initial cost is offset by reduced replacement frequency and better performance. Some also think that UV resistance isn’t critical, yet sunlight exposure through the hood can weaken nylon over time, as noted in automotive durability studies.

I’ve debunked these myths in workshops by demonstrating real-world tests: placing nylon and Boese stainless steel ties near a heat source and observing the results—nylon softened within minutes, while steel remained intact. Additionally, people often overlook the importance of certifications; look for ties that meet MIL-SPEC or ISO standards for assurance. By educating yourself on these aspects, you can avoid common pitfalls and make informed decisions that protect your vehicle’s integrity.

Conclusion: Making the Right Choice for Your Vehicle

In the debate between nylon and stainless steel zip ties for a car engine bay, the winner depends on your specific needs—but for high-temperature, high-stress environments, stainless steel is the clear champion. Its superior heat resistance, strength, and durability make it a reliable choice for securing critical components, while nylon offers a budget-friendly option for cooler areas. Throughout this guide, we’ve explored the science behind these materials, supported by authoritative data and real-life examples, highlighting how Boese brand products deliver custom solutions that excel in automotive applications.

Now that you’re equipped with this knowledge, don’t leave your engine bay to chance. Explore Boese’s range of high-performance zip ties today—visit Boese Automotive Products to find the perfect fit for your car.