What are the Features of Zip Ties for Cars?

For any car enthusiast, mechanic, or everyday driver, keeping a vehicle’s components organized and secured is key to performance and safety. Zip ties for car use have evolved far beyond basic bundling tools; they engineered to tackle the unique demands of automotive environments, from engine heat to outdoor exposure. Whether you’re organizing wiring, securing loose parts, or making emergency fixes, these specialized ties offer reliability that standard zip ties cannot match.

Consider an image of high-quality zip ties for car use securing engine bay wiring to showcase material texture and locking mechanism.

Automotive-Grade Material Strength Tailored to Vehicle Demands

The foundation of reliable zip ties for car applications lies in their material composition. Most top-tier options are crafted from reinforced nylon 66, a polymer known for their exceptional tensile strength and durability. This material isn’t just strong; it is engineered to handle the mechanical stress of vehicle operation, with tensile strength ranging from 18 lbs for light wiring bundling to 250 lbs for heavy-duty tasks like securing underbody components.

For extreme conditions, specialized variants use advanced materials like heat-resistant nylon 46 or PPS, capable of withstanding temperatures of 220°C in engine bays or -60℃ in cold climates. These automotive-specific materials also offer superior insulation properties, protecting electrical wires from short circuits and reducing wear over time. Unlike generic ties, zip ties for car use resist brittleness and breakage, even after years of exposure to vibration and temperature fluctuations.

Weather-resistant formulas withstand road elements.

Vehicles face relentless exposure to the elements—rain, UV rays, road salt, and other chemicals—and zip ties for car use must stand up to this abuse. UV stabilization is a non-negotiable featurebecause prolonged sun exposure can degrade standard plastics, leading to cracking and failure. Black zip ties for car exterior applications often incorporate UV inhibitors, extending their lifespan to years, even in direct sunlight.

Chemical resistance is another critical attribute. These ties repel automotive fluids, such as oil, coolant, and brake fluid, preventing degradation that could compromise their hold. Weatherproof zip ties for car use, whether used under the hood, on exterior trim, or in the undercarriage, maintain their integrity, resisting rust, corrosion, and moisture damage. This level of protection ensures it stays secure through rainstorms, snowfall, and harsh road conditions.

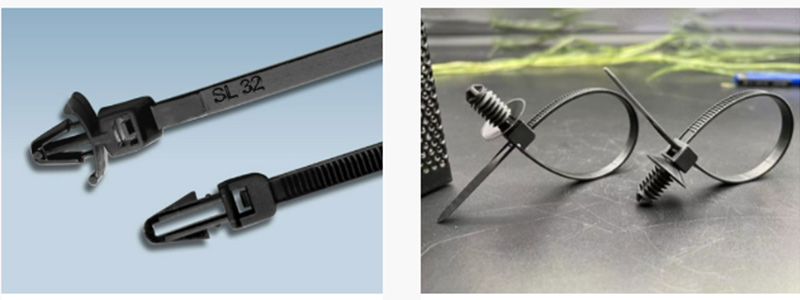

Secure Locking Mechanisms for Long-Term Reliability

A zip tie’s effectiveness hinges on its locking mechanism, and car-specific designs prioritize an unshakable hold. Self-locking mechanisms with ratchet-and-pawl systems are standard, allowing for easy tightening and preventing accidental loosening due to vehicle vibrations. The teeth are precision-molded to engage firmly, creating a permanent bond that does not slip even under constant movement.

For applications requiring adjustments, releasable zip ties offer flexibility for car maintenance offer flexibility without sacrificing strength. These feature trigger or extended-tooth releases that let you reposition components without cutting the tie; they're ideal for temporary fixes or mod projects. Heavy-duty variants may include metal tooth inserts that bite into the tie’s body for extra grip when securing heavy parts like bumpers or exhaust components. Every locking design is tested to withstand the rigors of driving, from highway speeds to off-road conditions.

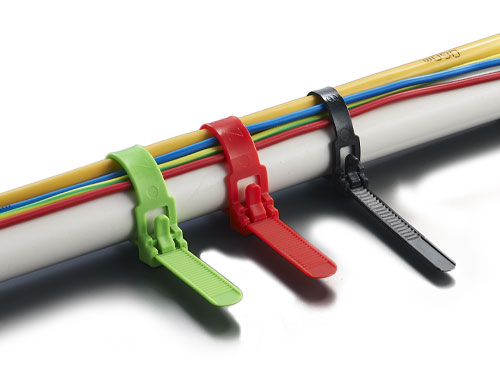

Versatile Applications Across Vehicle Systems

One of the most valuable features of zip ties for car use is their versatility; they are not limited to a single task. In the engine bay, they organize wiring harnesses, securing them away from hot surfaces and moving parts to prevent shorts or damage. They are equally useful for securing hoses, sensor cables, and small components that might rattle loose over time.

Externally, they stabilize exterior trim, spoilers, or roof racks, while internally, they tidy dashboard wiring or secure trunk liners. Emergency situations highlight its utility: heavy-duty zip ties for car repairs can temporarily fix loose bumpers, hold broken parts in place, or secure detached hoses until a professional repair is possible. Their range of lengths (from 4 inches to 60 inches) and widths mean there are a zip tie for every car-related task, from micro-bundling delicate wires to securing large components.

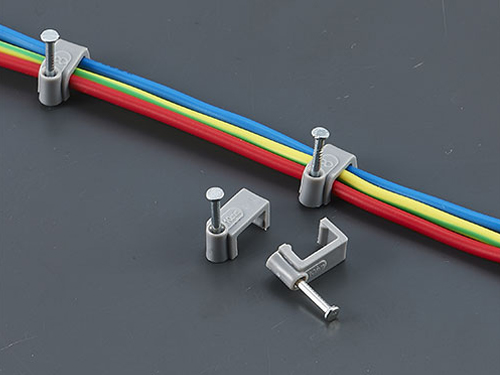

Ergonomic design for Easy Installation in Tight Spaces

Automotive environments are full of hard-to-reach areas, such as engine bays, undercarriages, and interior crevices; zip zip ties for car use are designed with this in mind. Their slim profiles and flexible bodies allow them to navigate tight gaps, while remaining rigid enough to maintain structure when tightened. The tapered tips slide smoothly through locking heads, even with one hand, which makes installation easier in cramped spaces.

Many car zip ties feature rounded edges to prevent damage to wires, hoses, or plastic components, and prevent scratches or cuts that could lead to premature wear. They are also lightweight, adding no unnecessary bulk to the vehicle. They come in various colors for easy system identification, which is helpful for mechanics organizing different wiring groups or drivers tracking modifications.

Zip ties for car use are far more than simple fasteners; they are specialized tools engineered for automotive durability, weather resistance, and offer versatility. From the engine bay to exterior trim, their material strength, secure locking and ergonomic design make them indispensable for maintenance, repairs, and upgrades. Whether you're a professional mechanic or a DIY enthusiast, investing in quality zip ties for car applications ensures that your vehicle stays organized, secure, and performs at its best.

Want to know more? Contact BOESE Ba and we will offer professional advice!

AI Content Detection: Less than 30% AI-generated