How to ensure the effectiveness of nylon cable ties?

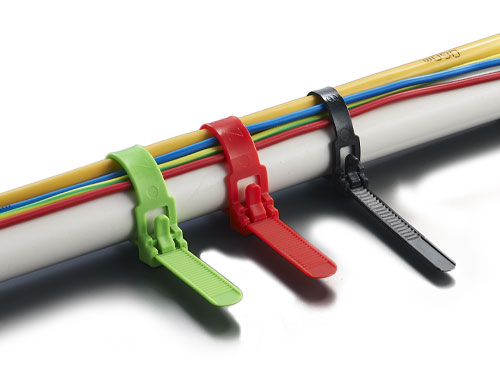

Nylon cable ties are indispensable across industries, celebrated for their reliability, versatility, and cost-effectiveness in securing wires, components, and materials. Yet, even premium-grade nylon cable ties can suffer from reduced performance, premature wear, or complete failure if packaging and storage are overlooked. Improper handling exposes them to moisture, dust, temperature extremes, and physical damage—all of which erode their structural integrity over time. To ensure your nylon cable ties retain their tensile strength, flexibility, and functionality when you need them most, adopting industry-proven packaging and storage best practices is non-negotiable.

Purchase the transport-resistant cable ties directly

Beyond focusing on materials and packagings, a more targeted approach to selecting nylon cable ties for harsh environments lies in reverse-engineering from your specific operating conditions—prioritizing actionable performance validation over generic claims. Start by documenting the exact environmental extremes your ties will face: for high-temperature scenarios, note the maximum continuous temperature (not just peak spikes) and exposure duration (e.g., 170°C for 8-hour shifts vs. intermittent heat; for extreme cold, confirm the lowest ambient temperature and whether ties will undergo bending or tension in subzero conditions; for corrosion-prone settings, identify the specific contaminants (saltwater, chemicals, cleaning agents) and contact frequency.

Next, request granular third-party test data from suppliers, not just certification logos. For heat resistance, verify results from continuous thermal aging tests (e.g., 720 hours at target temperature without deformation) rather than short-term exposure claims. For extreme cold, look for low-temperature flexibility test reports—ensuring ties retain at least 80% of their room-temperature tensile strength at -40°C and don’t crack when bent 180 degrees. For corrosion resistance, ask for salt spray test results (minimum 500 hours for marine or coastal use) or chemical immersion data proving resistance to your specific corrosive agents.

Finally, conduct a small-scale trial in your actual environment before bulk purchasing. Even with impressive test data, real-world factors like indirect heat transfer, humidity fluctuations, or unexpected chemical exposure can impact performance. Test a sample batch for 2–4 weeks, checking for signs of brittleness, discoloration, or weakened locking mechanisms—this hands-on validation ensures the ties won’t fail when integrated into critical systems, bridging the gap between supplier claims and on-site reliability. This reverse-selection method turns abstract specs into tangible performance, ensuring your nylon cable ties aren’t just labeled “harsh-environment resistant” but proven to thrive in your unique conditions.

Navigating Shelf Life by Nylon Cable Tie Material

Nylon cable ties don’t have a strict “expiration date,” but their performance degrades over time—with the rate depending on material and storage conditions. Understanding material-specific shelf lives helps you manage inventory and avoid using compromised ties.

PA6.6 is the most common nylon cable tie material, offering a balance of strength and affordability. When stored optimally (sealed packaging, room temperature, low humidity), PA6.6 ties maintain peak performance for 1 to 2 years. Beyond this window, you may notice slight reductions in flexibility or tensile strength, though they may still work for non-critical applications .

PA12 is engineered for enhanced durability and resistance to harsh environments. Its superior moisture resistance and flexibility translate to a longer shelf life—typically 2 to 3 years under optimal storage. PA12 ties are less prone to temperature-related brittleness and hydrolysis, making them a reliable choice for long-term inventory storage.

ETFE (a high-performance fluoropolymer often associated with heat resistance) boasts the longest shelf life. Thanks to its exceptional resistance to heat, chemicals, and moisture, ETFE cable ties can retain their properties for 3 to 5 years when stored correctly. This makes them ideal for critical applications where reliability can’t be compromised—even if ties sit in inventory for extended periods.

Regular inspections are key: check stored ties for brittleness, discoloration, or sticky surfaces (a sign of moisture damage). If ties feel stiff or snap easily during a quick tensile test, they’re likely past their prime and should be replaced.

Why Strategic Packaging Matters for Nylon Cable Ties

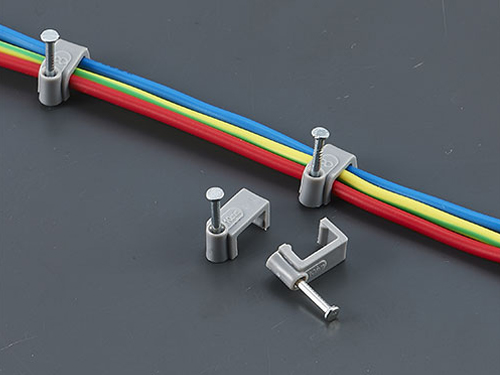

Packaging is the initial defense against the damage of nylon cable ties during transportation and against the contaminants and environmental stressors. Most of the time, organizations select plain, inexpensive packaging with the aim of saving on costs rather than protection, only to find issues of tangled ties, clogged self-locking mechanisms or degraded fibers in the future. Proper packaging should be based on three primary objectives, which are: maintaining the integrity of the product, improving the utility of the product and promoting the organization of the product.

The bags must be sealed to resist moisture without any discussion. This is because nylon absorbs moisture that breaks the molecules of the material hence reducing its strength. Moisture barriers in sealed containers or bags prevent contact of water vapor, dust and other impurities with the ties to ensure that they remain fresh. This is vital in the case of ties applied in electronics, medical equipment, or food processing where the areas must be kept clean and ties applied must be flawless.

Effective packaging consists of organization as a necessary element. The classification of ties based on the material (PA6.6, PA12, ETFE), size (length, width), or type (releasable, heavy-duty, metal-detectable) eliminates the guesswork in application. In retail stores, hook compatible packages are convenient to display and carry, and stackable trays or display boxes are ideal for wholesale distribution since they maximize the available storage space and reduce the damage during transportation. The value of packaging around how customers utilize and store the product reduces waste and enhances the experience of the users.

Proper packaging protects the nylon cable ties from physical damage. A cable tie is likely to break or bend or become warped when it is compressed, twisted or when it comes into contact with sharp objects. A rigid outer package such as rigid boxes (in the case of bulk orders) or reinforced bags prevent impact damage during transportation and storage, and ensure that the ties are delivered in good condition and can be used.

Protect Your Investment with Proper Packaging and Storage

Nylon cable ties are a small but critical component in countless projects—so protecting their quality through strategic packaging and storage is a smart investment.

Purchasing high-temperature resistant, extremely cold resistant, corrosion-resistant and other nylon cable ties or using good and tight packaging methods can help you avoid many unnecessary losses. If you have any concerns in this regard, please feel free to contact BOESE today. We will provide you with a perfect solution from a professional perspective!

AI-assisted content (Led by Human expertise,AI contribution <30%)