How to choose nylon cable ties? Three key selection dimensions from temperature to load-bearing capacity

Nylon cable ties are widely used in industries like electronics, construction, and logistics for organizing wires, securing components, and bundling items. However, choosing the right nylon cable tie is not a random task—picking an improper one may lead to loosening, breakage, or even safety hazards. Below are three key dimensions to guide your selection, helping you find the most suitable nylon cable tie for your needs.

1. Temperature Resistance

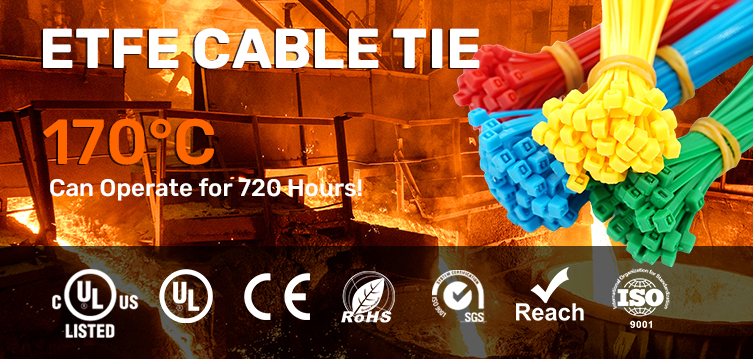

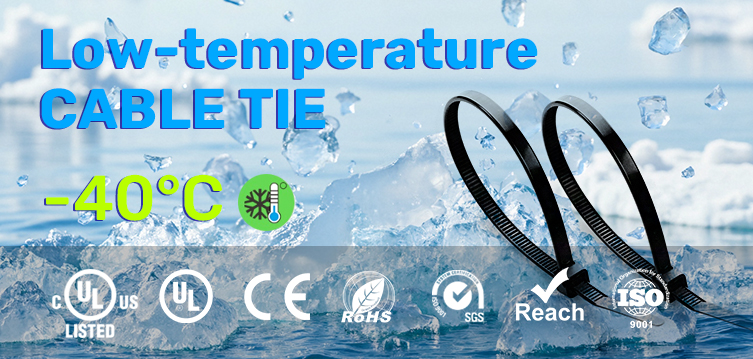

Temperature is a critical factor affecting the performance of nylon cable ties, as extreme temperatures can weaken their toughness or cause brittleness. When evaluating this dimension, focus on the following points:

•Understand the temperature range: Regular nylon cable ties work well in a common temperature range, typically from around -40°C to 85°C. For high-temperature scenarios like near industrial ovens or engine compartments, opt for heat-resistant nylon cable ties that can withstand temperatures above 100°C for extended periods.

•Consider temperature fluctuations: If the working environment has frequent temperature changes (such as outdoor areas with day-night temperature differences), choose nylon cable ties with good thermal stability to avoid cracking due to repeated expansion and contraction.

•Check low-temperature performance: In cold regions or refrigeration environments, ensure the nylon cable tie won’t become brittle and snap easily at low temperatures. Some specialized low-temperature nylon cable ties maintain flexibility even below -30°C.

2. Load-Bearing Capacity

The load-bearing capacity of a nylon cable tie determines how much weight it can safely hold without breaking. Ignoring this may result in the tied items falling off. Here’s how to assess it:

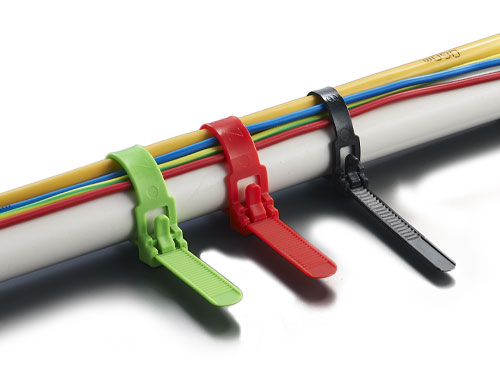

•Look at the rated load, not just the appearance: Each nylon cable tie has a rated load (often marked by the manufacturer). Choose one with a rated load higher than the actual weight of the items you’ll bundle—leaving a certain safety margin is wise, as sudden vibrations or impacts may increase the load temporarily.

•Relate to size specifications: Generally, wider and thicker nylon cable ties have higher load-bearing capacity. For example, a 4.8mm-wide heavy-duty nylon cable tie can bear more weight than a 2.5mm-wide standard one. But don’t just pursue large size; match it to your actual bundling needs to avoid waste.

•Note the installation method: The way you fasten the nylon cable tie affects its load-bearing. Avoid over-tightening (which may damage the tie) or under-tightening (which reduces stability). Ensure the locking mechanism is fully engaged to maximize load-bearing performance.

3. Material & Environmental Compatibility: Ensure Long-Term Use

The material of nylon cable ties and their compatibility with the surrounding environment directly impact their service life. Pay attention to these aspects:

•Resistance to chemicals: If the nylon cable tie will be exposed to oils, solvents, or weak acids/alkalis (such as in automotive maintenance or chemical plants), select chemical-resistant nylon cable ties. Regular ones may degrade when in contact with these substances, losing their strength over time.

•UV resistance for outdoor use: Outdoor applications (like securing solar panel wires or garden fences) require UV-resistant nylon cable ties. Ordinary nylon cable ties will become brittle and break after several months of sun exposure, while UV-resistant ones can retain performance for years.

•Special requirements for specific industries: For food processing or medical equipment, choose food-grade nylon cable ties that meet relevant safety standards—they are non-toxic and won’t contaminate food or medical supplies.

Conclusion

Choosing the right nylon cable tie requires considering temperature resistance, load-bearing capacity, and material-environment compatibility. By matching these three dimensions to your actual application scenario, you can ensure the nylon cable tie is durable, safe, and effective. Don’t just focus on price—poor-quality nylon cable ties may cause more troubles in the long run.

Ready to find the perfect nylon cable tie for your project? Visit BOESE to browse our full range of products, including heat-resistant, heavy-duty, and UV-resistant nylon cable ties. Our team can also provide personalized recommendations based on your needs—contact BOESE today to get started!