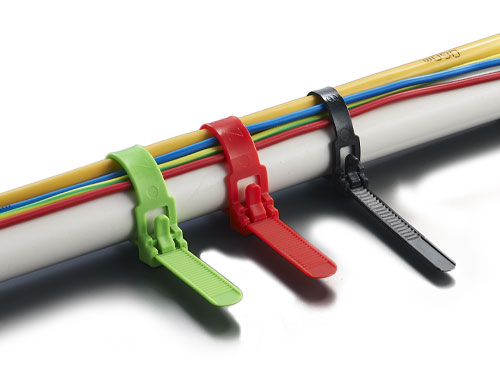

Global Zip Tie Market Analysis: Regional Trends & Competitive Insights

The humble zip tie, a staple in industrial and consumer applications worldwide, is undergoing a quiet revolution. From aerospace engineering to smart agriculture, today's nylon cable ties are far more than simple fasteners—they're precision-engineered solutions driving efficiency across industries.

1. Regional Demand & Leading Zip Tie Manufacturers

A. Asia-Pacific (Dominant Production Hub)

- China: Accounts for ~60% of global nylon cable tie manufacturing, with key players like:

- *Hua Wei (Specialty: UV-resistant & heavy-duty industrial ties)

- *Yueqing (Key Strengths: Bulk supply, competitive pricing)

- India: Rapid growth in automotive & consumer electronics driving demand.

- Japan/Korea: Focus on high-tensile, precision-grade zip ties for robotics.

Market Fact: China exports over $800M/year in zip ties, with 25% going to North America & Europe.

B. North America (Premium & Custom Solutions)

- Top Suppliers: Thomas & Betts, HellermannTyton (now Aptiv), Panduit

- Trends:

- *Fire-resistant cable ties for aerospace/military.

- *Smart inventory tracking ties (RFID-enabled).

- Buyer Priority: Compliance with UL/CSA certifications.

C. Europe (Sustainability-Driven Innovations)

- Regulations: EU’s Single-Use Plastics Directive pushes biodegradable alternatives.

- Key Players:

- *Cablecraft (UK): Leader in recycled-nylon ties.

- *Fischer (Germany): High-strength ties for wind turbine wiring.

2. Competitive Benchmarking: Top 5 Global Suppliers

| Manufacturer | Strengths | Weaknesses |

|---|---|---|

| HellermannTyton | Broad industrial solutions, IoT-ready | Higher pricing vs. Asian OEMs |

| Panduit | Best for data centers & telecom | Limited eco-friendly options |

| Hua Wei (China) | Cost-efficient bulk supplier | Minimal customization |

| NSi Industries (US) | Releasable tie specialist | Smaller global distribution |

| Novoflex (Germany) | Precision medical/automotive grades | Lead times for exports |

3. Future Outlook: Where Is the Market Headed?

- Africa/Middle East: Emerging demand for construction-grade ties (Dubai Expo 2030 projects).

- Latin America: Growth in agricultural & automotive cable ties.

- Tech Disruption: AI-driven QC in manufacturing cuts defect rates by 15% (2025 projection).

Conclusion

The zip tie market is evolving at the speed of industry itself. While Asian Nylon Cable Tie Manufacturers continue leading in cost-effective bulk production, Western firms are pivoting to high-margin niches like flame-retardant and smart ties. Meanwhile, sustainability mandates are reshaping material innovation across Europe.

Three key takeaways:

- Diversify suppliers: Blend Asian cost efficiency with Western technical specialization

- Future-proof purchases: Prioritize suppliers investing in IoT-compatible and eco-friendly ties

- Watch regulations: EU plastic laws and UL certifications will dictate future trends

As infrastructure and renewable energy projects boom globally, strategic partnerships with innovative zip tie manufacturers will separate industry leaders from the pack. The next revolution? Perhaps self-tightening AI-monitored ties—but that's an analysis for 2025.

Need durable, innovative zip ties? Partner with a trusted cable ties manufacturer today—request a free sample!