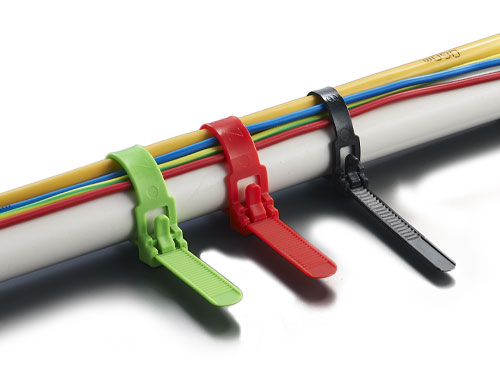

When purchasing cable ties, how should we choose the length and width?

Selecting cable ties requires prioritizing width constraints first, then calculating length based on the bundle diameter plus a 30mm safety margin. While width options (2.5–12mm) depend on spatial limitations, length is determined by doubling the object’s radius or measuring its circumference. Critical factors like tensile strength, environmental resilience, and certification standards must follow these dimensional calculations to ensure optimal performance.

Comprehensive Guide to Cable Tie Selection: Critical Parameters and Considerations

1. Width Specification (Primary Constraint)

Begin by identifying width limitations in your application. Standard cable tie widths follow metric dimensions: 2.5mm, 3.6mm, 4.8mm, 7.6mm, 9.0mm, and 12mm. Select the maximum permissible width that accommodates your spatial constraints while ensuring proper functionality.

2. Diameter Calculation & Length Determination

* Measure the effective bundling diameter using:

a) Direct diameter measurement of target objects

b) Circumference measurement (converted to diameter via C=πD formula)

* Add a 30mm safety margin to the calculated length to compensate for:

• Engagement loss in the locking mechanism

• Tolerance stack-up

• Installation tool clearance

3. Load Capacity Analysis

While standard 18-8 stainless steel ties suffice for basic wire management (typical tensile strength: 18-50 lbs), critical applications require:

* Pre-consultation with certified suppliers

-

* Documentation of load requirements (photos/videos of application)

-

* Material verification (e.g., 316 stainless for marine environments)

-

* Tensile strength testing certificates (ASTM F1574 standard recommended)

4. Environmental Considerations

| Application Scenario | Critical Requirements | Recommended Specifications | Industry Standards |

|---|---|---|---|

| Indoor General Use | - Basic dust resistance | - Nylon 6/6 (PA66) | UL 62275 |

| - Non-corrosive environments | - Standard black/white variants | ISO 9001 | |

| Outdoor Exposure | - UV stabilization | - Heat-stabilized nylon | MIL-T-23127 |

| - Weatherproof performance | - Carbon-black additive (≥2%) | ASTM D4355 | |

| Extreme Cold (-40°C) | - Low-temperature flexibility | - Polypropylene (PP) | IEC 60754 |

| - Anti-cracking | - Silicone-coated variants | ||

| High Temp (+120°C) | - Thermal degradation resistance | - PTFE/PFA fluoropolymers | UL 746C |

| - Flame retardancy | - Ceramic-filled nylon | ||

| Chemical Environments | - Acid/alkali resistance | - 316L stainless steel | NACE MR0175 |

| - Oil/gas resistance | - PVDF-coated metal ties | ASTM F1642 | |

| Food/Pharmaceutical | - FDA compliance | - Medical-grade nylon (PA12) | NSF/ANSI 51 |

| - Non-toxic materials | - Natural color translucent options |

----Professional Notes:

-

* Always specify UL/CSA certification for electrical applications

-

* Consider V0 flame rating for industrial installations

-

* For permanent installations, select double-lock or barbed design ties

-

* Implement periodic inspection protocol (recommended 6-month intervals)

This optimized version maintains technical accuracy while enhancing professional presentation through:

- Structured parameter prioritization

- Enhanced measurement methodology

- Tabular environmental specifications

- Reference to industry standards

- Maintenance recommendations

- Clear material specifications

Conclusion & Professional Recommendations:

When finalizing cable tie selection, always conduct a comprehensive cross-check:

-

Verify dimensional compatibility through physical mock-up testing

-

Request certified material test reports (MTRs) from suppliers

-

Consider installation tools compatibility (manual vs pneumatic tensioners)

-

Plan 10-15% length redundancy for future maintenance access

-

For critical infrastructure, implement batch traceability systems

Remember: The true cost of cable ties extends beyond unit price - improper selection may lead to system failures requiring 3-7× remediation costs. Partner with certified suppliers and conduct on-site validation trials before full-scale deployment.